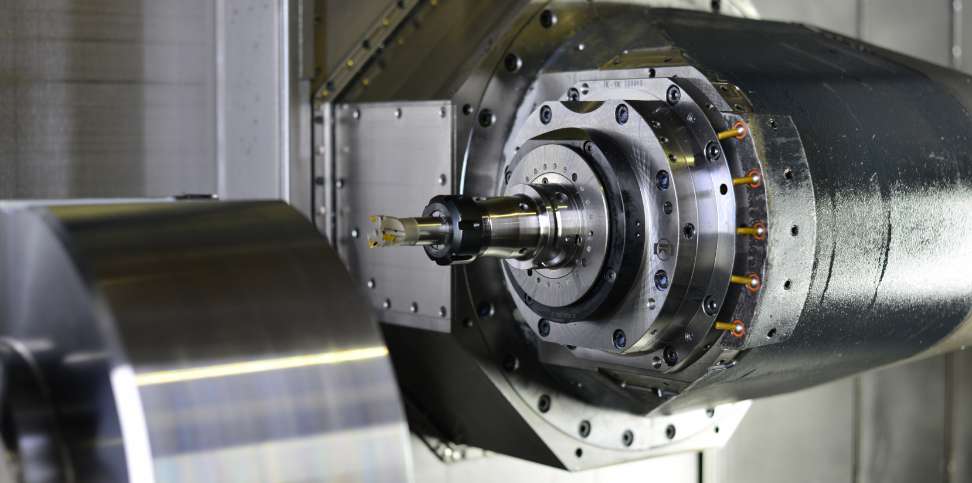

If you need a replacement spindle for a CNC or similar machine, you may have become distressed by their high cost. A new spindle could cost as little as $100 or as much as $1000 or more, depending on the specific model you need. Luckily, there is the option to purchase a used spindle that works just as well but at a much more affordable price. Buying a used spindle can be a great alternative to purchasing a new one, but more precautions need to be taken when buying a used part as opposed to a new one. If you’re going the used route, then there are four key considerations to ensure you’re making an excellent choice and that the spindle will work as you expect.

Table of Contents

How Has the Used Spindle Been Used in the Past?

While it might seem to most people that a machine spindle is a machine spindle, and as long as it fits your machine and can operate, it’s an adequate replacement. Unfortunately, used spindles don’t work that way. Even though the used spindle might fit your machine, it may have previously been used in a different machine that is completely different from how you need to use it. This could pose a problem, so you should ensure that the used spindle is an exact match before making a purchase. You don’t want to end up stuck with a spindle that you can’t use and probably can’t return or replace.

Where You Opt to Purchase Your Spindle

Where you choose to purchase your used spindle is important, so refrain from making rash decisions when buying one. Unfortunately, not every used spindle dealer is trustworthy, and you could end up wasting money on a previously owned spindle that can’t be used. Unscrupulous sellers are prevalent, so even if a dealer appears honest, check out their background before committing. Even if you hire an agent to locate the perfect spindle for you, make certain that your agent is also honest. While it may seem like an unnecessary hassle, it’s very important to research legitimate spindle dealers and agents before choosing to do business with anyone. Many criminals in the world make a living off other people’s misfortunes. Therefore, selling someone a useless spindle isn’t a big deal for these types of people. If you take your time searching for the perfect dealer or agent, you shouldn’t experience any problems.

The Condition of the Used Spindle

Another important consideration when purchasing a used spindle is how “used” it is. Buying an old spindle on its last leg will likely cause you to end up in the same situation you’re in now – in search of a replacement spindle. If it even works, you don’t want to waste time and money on a spindle that will stop working soon after you purchase it. Not all dealers provide warranties when purchasing used materials, so be sure to determine the specifics before you agree to purchase.

Before making a deal, you need to find out how long it has been since the spindle was last used, what type of environment it has been stored in, what the taper condition of this shaft is, as well as the manual and all maintenance logs. Be sure to carefully inspect the spindle before finalizing the deal, and if a deal seems too good to be true, then it probably is. Don’t be afraid to walk away from a prospective deal if a used spindle appears to be in poor condition or if an agent or dealer behaves suspiciously.

You might find a used spindle that needs to be modified in some way to work efficiently. That is fine as long as the cost for the spindle itself, and the repairs don’t add up to more than what it’s worth. If the costs add up to too much, you could pay as much as you would for a brand-new one. So, be sure to find out about specific costs in advance, and if it needs repairs, be sure to obtain a reliable quote before making the purchase.

Choosing the Specific Spindle

This is probably the most important one of the other three considerations you need to make when buying a used spindle. You must ensure you choose the exact part required for your machine. Many spindles often have the same first three or four numbers when it comes to serial numbers. However, the numbers that come after the first few differentiate one spindle from another. Purchasing and using the wrong spindle on a machine could have some negative consequences. This could lead to costly repairs, extended downtime, and significant machine damage. So, before you purchase a used spindle, be sure to verify that it’s the precise spindle you need and that it will work efficiently in the machine you need it for.

As you can see, it’s possible to find a used spindle in excellent condition but for a much lower price than buying a brand-new one. As long as you keep these four considerations in mind, you shouldn’t have any problems, and you should end up with a high-quality, fully functional spindle that makes your CNC machine work like new. However, if you ignore these considerations and end up purchasing a spindle that isn’t appropriate for your specific machine, you could be making a very costly mistake. Such a mistake could unnecessarily extend downtime, causing your company to lose money.

RELATED ARTICLES

Latest Articles

Creating Dynamic Content Calendars Within a Headless CMSIn TipsMarch 27, 2025When you’re syndicating content for different […]

Creating Dynamic Content Calendars Within a Headless CMSIn TipsMarch 27, 2025When you’re syndicating content for different […] Florida’s Harsh Sun & Your Car: How to Prevent Paint Damage with PPFIn AutomotiveMarch 27, 2025Florida is known for its year-round sunshine, but that […]

Florida’s Harsh Sun & Your Car: How to Prevent Paint Damage with PPFIn AutomotiveMarch 27, 2025Florida is known for its year-round sunshine, but that […] 5 Cool Apps You Probably Didn’t Know AboutIn AppMarch 19, 2025We’ve all heard of mainstream apps such as Facebook, […]

5 Cool Apps You Probably Didn’t Know AboutIn AppMarch 19, 2025We’ve all heard of mainstream apps such as Facebook, […] Top 5 Most Downloaded Apps in the App Store in 2024In TipsMarch 13, 2025The App Store continues to be a hotspot for new and […]

Top 5 Most Downloaded Apps in the App Store in 2024In TipsMarch 13, 2025The App Store continues to be a hotspot for new and […] Top 5 Digital PR and Link-Building Agencies in 2025 for SEO GrowthIn TechnologyMarch 10, 2025In 2025, digital PR and quality backlinks will be […]

Top 5 Digital PR and Link-Building Agencies in 2025 for SEO GrowthIn TechnologyMarch 10, 2025In 2025, digital PR and quality backlinks will be […] How Long To Soak Chia Seeds: A Simple GuideIn TipsFebruary 11, 2025Chia seeds are little round black seeds that have […]

How Long To Soak Chia Seeds: A Simple GuideIn TipsFebruary 11, 2025Chia seeds are little round black seeds that have […] How to Spot Fake Software Licenses and Avoid ScamsIn TechnologyFebruary 4, 2025Image Credit: pexels.com In today’s complex […]

How to Spot Fake Software Licenses and Avoid ScamsIn TechnologyFebruary 4, 2025Image Credit: pexels.com In today’s complex […] What Factors Should Businesses Consider When Choosing A SIP Trunk Provider?In TechnologyFebruary 1, 2025Under the conditions that are related to running a […]

What Factors Should Businesses Consider When Choosing A SIP Trunk Provider?In TechnologyFebruary 1, 2025Under the conditions that are related to running a […] Best ATV Rentals in Dubai for Unforgettable Desert SafarisIn TravelJanuary 29, 2025Image Credit: pexels.com Dubai is a city that offers […]

Best ATV Rentals in Dubai for Unforgettable Desert SafarisIn TravelJanuary 29, 2025Image Credit: pexels.com Dubai is a city that offers […] The Evolution of Paint Protection Film: Innovations You Need to KnowIn TechnologyJanuary 26, 2025Over the years, Paint Protection Film (PPF) has […]

The Evolution of Paint Protection Film: Innovations You Need to KnowIn TechnologyJanuary 26, 2025Over the years, Paint Protection Film (PPF) has […] Your Ultimate Guide to Local SEOIn MarketingJanuary 17, 2025Local SEO can be defined as optimization of the online […]

Your Ultimate Guide to Local SEOIn MarketingJanuary 17, 2025Local SEO can be defined as optimization of the online […] Top 5 Reasons Why the Organic Traffic Is Really Beneficial for BusinessesIn MarketingJanuary 16, 2025Many companies invest heavily in SEO, with the […]

Top 5 Reasons Why the Organic Traffic Is Really Beneficial for BusinessesIn MarketingJanuary 16, 2025Many companies invest heavily in SEO, with the […]

stopie.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com.

Clicking on an Amazon link from stopie.com does not increase the cost of any item you purchase.

We will only ever link to Amazon products that we think our visitors may be interested in and appreciate learning more about.